Impeller Maintenance

This section of the manual provides a comprehensive guide on Impeller maintenance. It covers safety precautions, the tools and materials needed, detailed procedures for thruster change-outs and cleaning and inspection guidelines. By following these guidelines, operators can ensure Hydrus continues to perform at its best in all underwater operations.

Note: Hydrus hardware v1.1 uses simpler universal impellors, instead of clockwise/counter-clockwise impellors used by Hydrus hardware v1.0. Diagrams and instructions within this section show the hardware v1.1 impellors, but otherwise the instructions are the same.

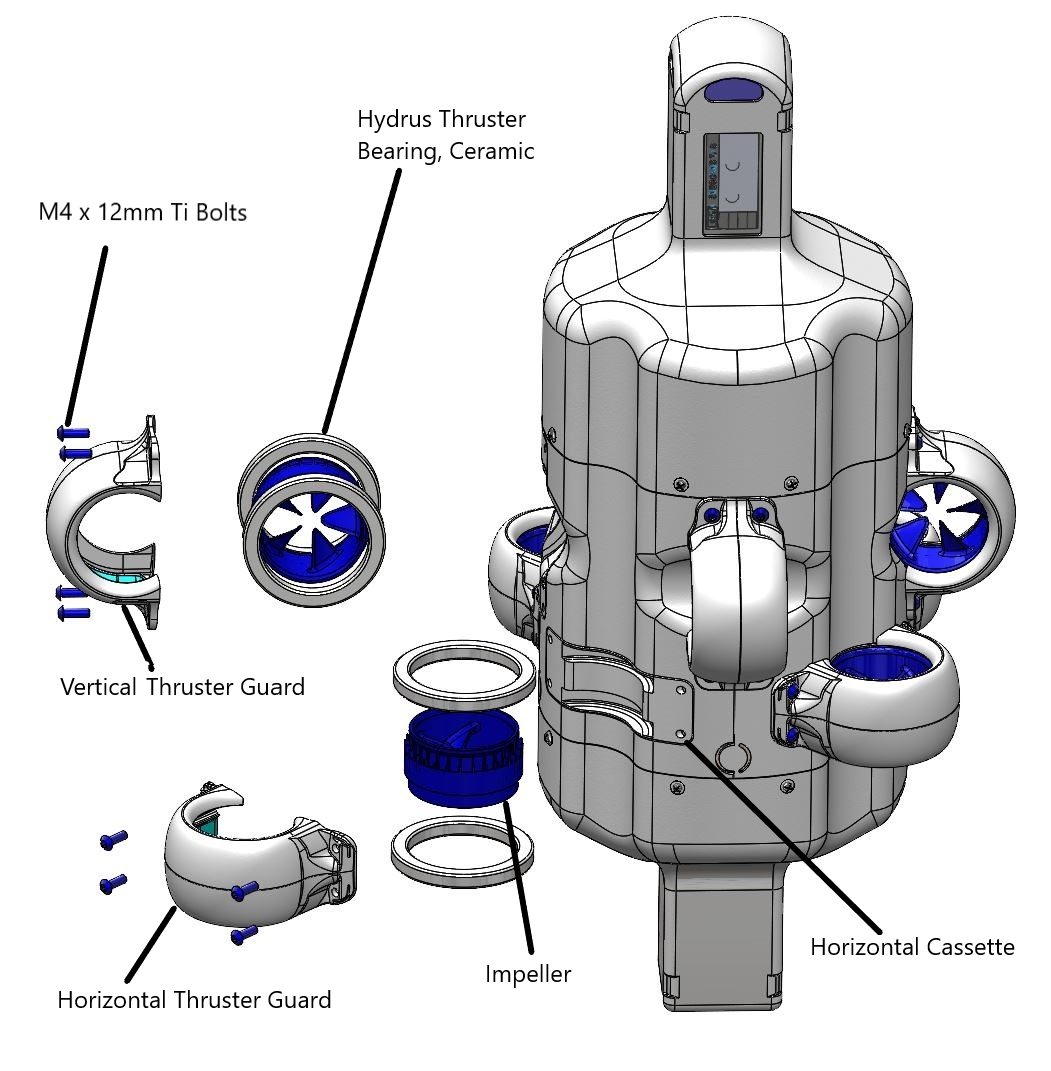

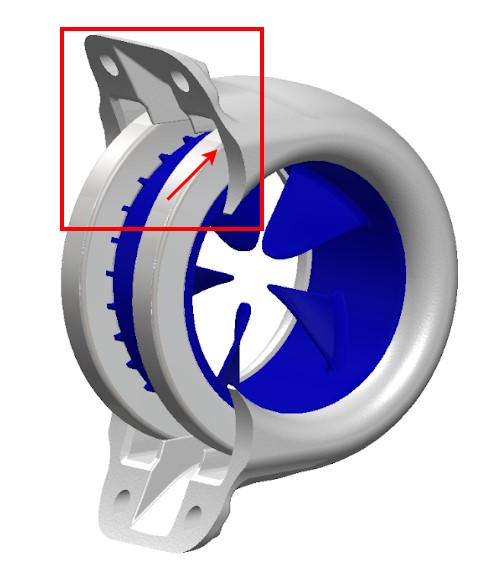

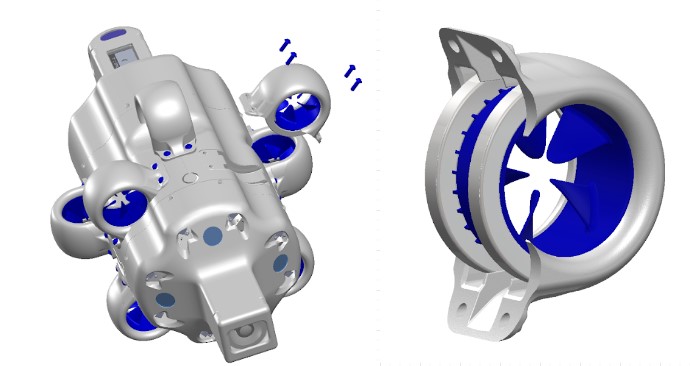

Thruster Assembly Exploded

Thruster Assembly Exploded

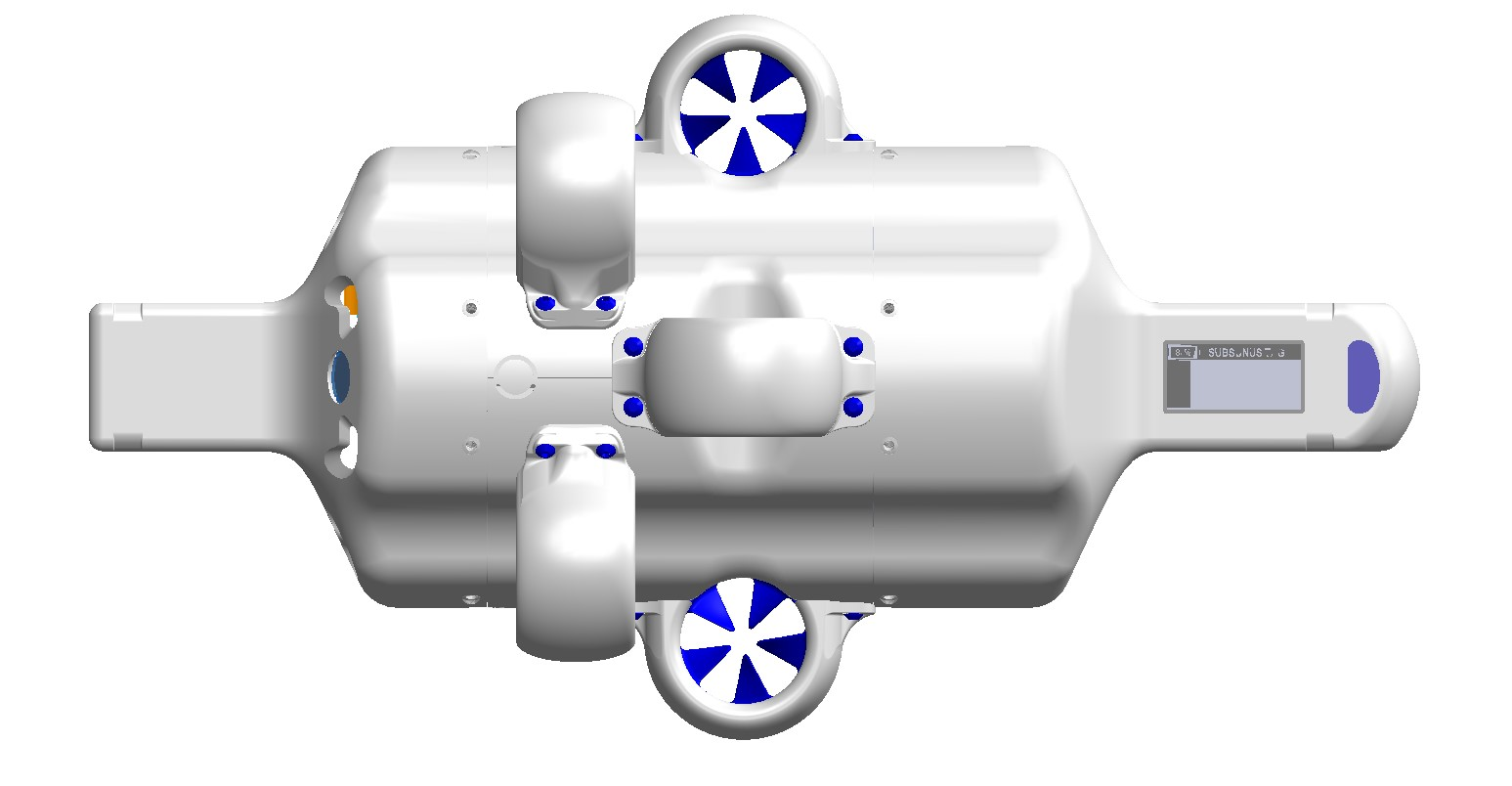

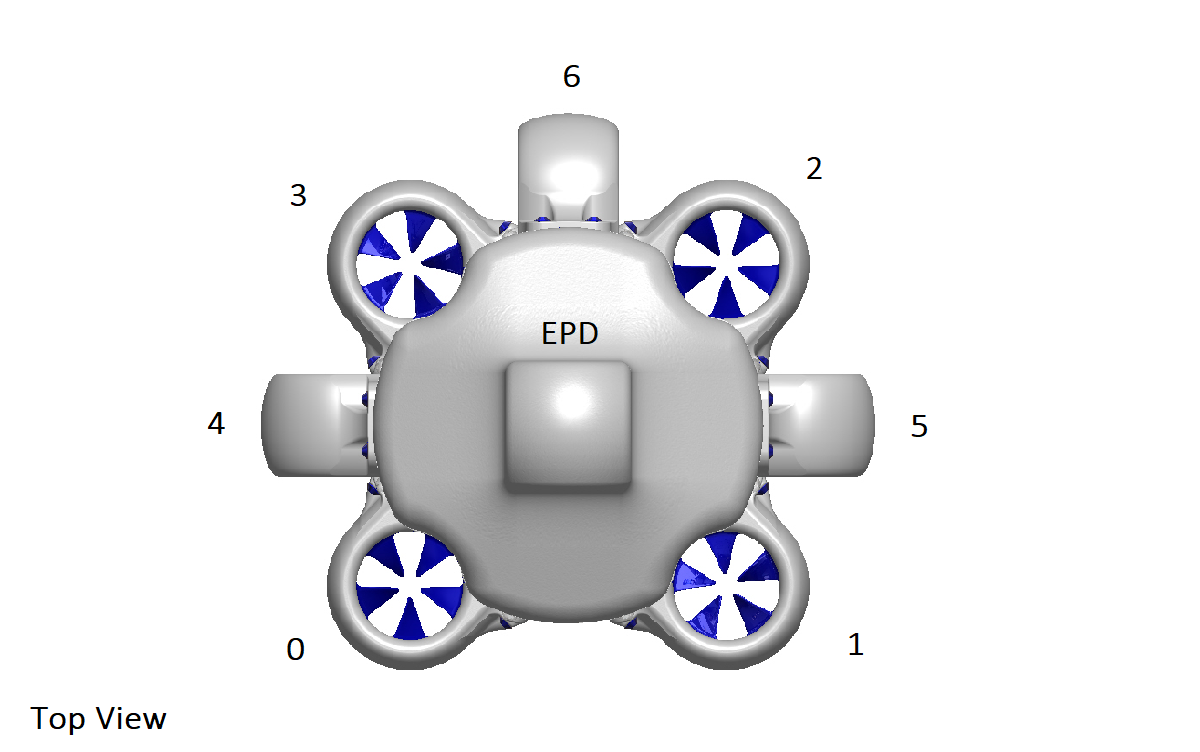

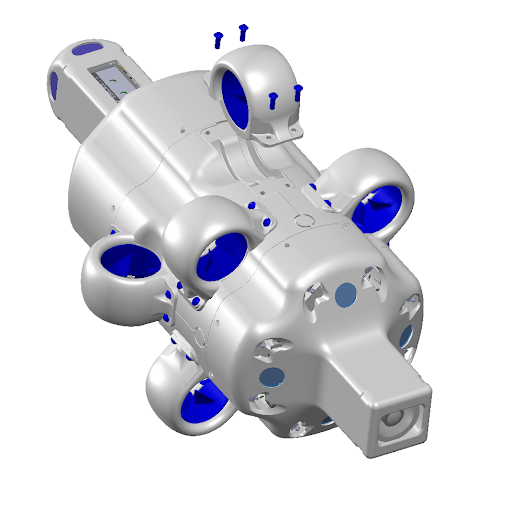

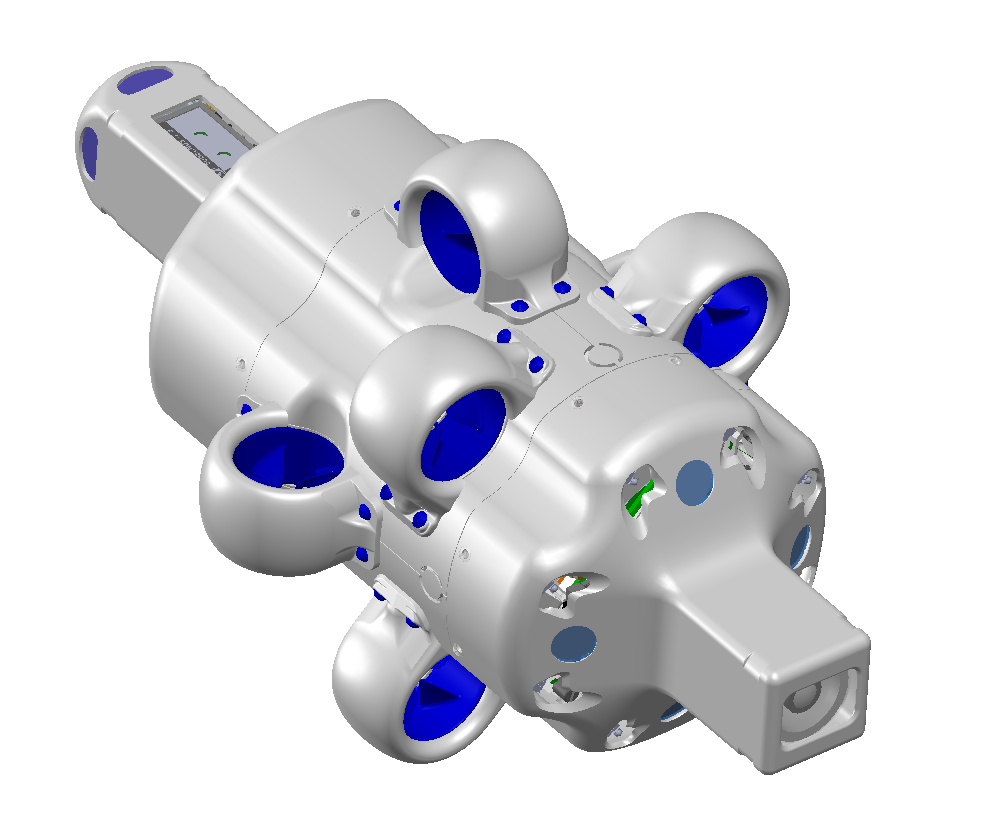

Thruster Layout

Note: Hydrus hardware v1.1 uses simpler universal impellors, instead of clockwise/counter-clockwise impellors used by Hydrus hardware v1.0. Diagrams and instructions within this section show the hardware v1.1 impellors, but otherwise the instructions are the same.

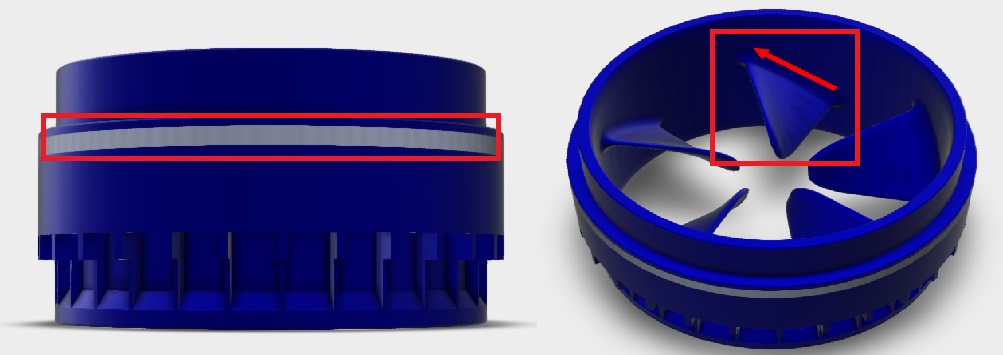

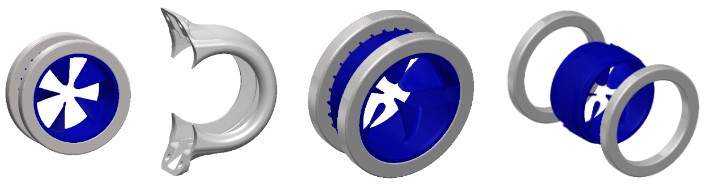

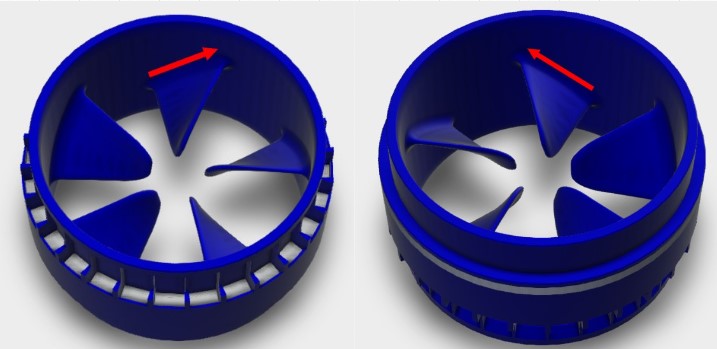

Clockwise (CW) Impellor

The CW Impellor can be denoted by a white ribbon around it's surface and the base of the impellor blade inclines towards the left.

Note: The CW Impeller can be inserted into the thruster guard either way up (white line up or down), there is no significance.

CW Top View Side View

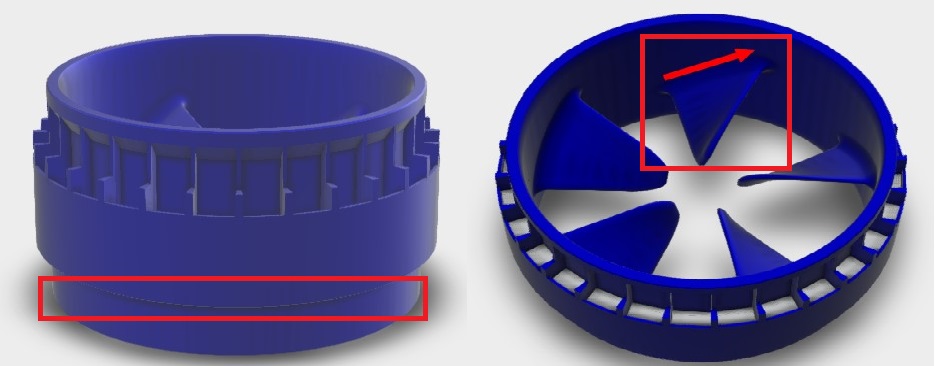

Counter Clockwise (CCW) Impellor

The CCW Impellor can be denoted by no ribbon on the surface of the impellor and the impellor blade base leans outwards towards the right.

Note: The CCW Impeller can be inserted into the thruster guard either way up, there is no significance.

CCW Top View Side View

Thruster Layout Complete

Thruster Layout Complete

Note: The following table applies to Hydrus hardware v1.0. Hydrus hardware v1.1 uses simpler universal impellors, instead of clockwise/counter-clockwise impellors used by Hydrus hardware v1.0.

| Thruster Number | Impellor Direction | Guard Type |

|---|---|---|

| 0 | Counter Clockwise (CCW) | Horizontal Guard |

| 1 | Clockwise (CW) | Horizontal Guard |

| 2 | Counter Clockwise (CCW) | Horizontal Guard |

| 3 | Clockwise (CW) | Horizontal Guard |

| 4 |

Clockwise (CW) |

Vertical Guard |

| 5 |

Counter Clockwise (CCW) |

Vertical Guard |

| 6 | Counter Clockwise (CCW) | Vertical Guard |

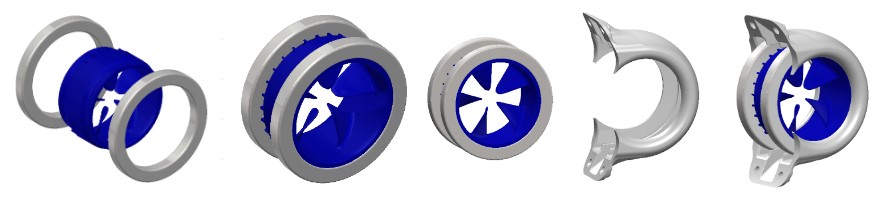

Horizontal Thruster Guard

The Horizontal Thruster Guard is a protective component designed to prevent damage to the thrusters of the Hydrus. The Horizontal Thruster Guard is characterised by a curvature of the base of the guard that aligns with the main body of Hydrus, the guard will house in the shallow cassette on the Hydrus which is depicted in the illustration below.

Horizontal Thruster Guard

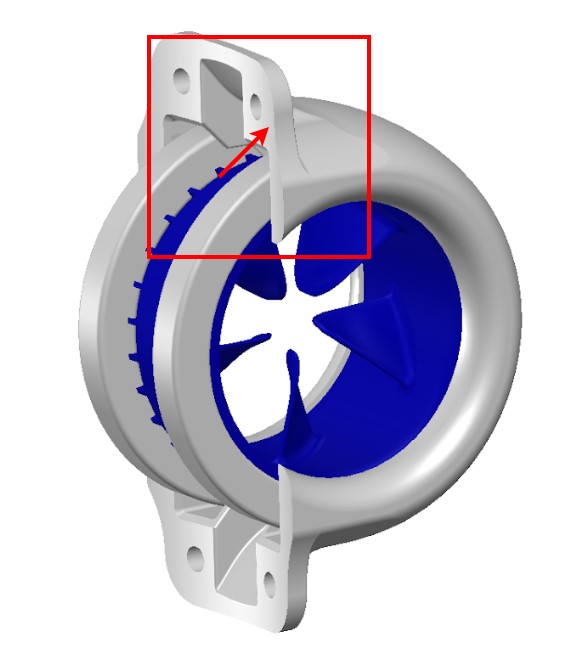

Vertical Thruster Guard

The Vertical Thruster Guard's design is distinct from the Horizontal Thruster Guard. While the Horizontal Thruster Guard is characterised by a curvature that aligns with the main body of Hydrus, the Vertical Thruster Guard has a base that is near straight and will sit in the deeper cassette on the Hydrus main body. see below for illustration.

Hydrus Flat Surface

Ceramic Bearings

The ceramic bearing is a disc-shaped assembly composed of a hollow ceramic ring. This ring includes an inner and outer raceway that encapsulates extremely hard and smooth ceramic balls. Each thruster assembly requires two of these ceramic bearings. They are positioned on either side of the impellor and are fit between the thruster guard and the thruster cassette.

Ceramic Bearing

Tools and Materials Needed

| Item | Quantity |

|---|---|

| 2.5mm Hex Head | 1 |

| Horizontal / Vertical Guard | 1 |

| Clockwise (CW) / Counterclockwise (CCW) Impellor | 1 |

| M4 x 12mm Bolts | 4 |

| Hydrus Thruster Bearing, Ceramic | 2 |

Thruster Guard Removal: Using the 2.5mm hex key, carefully unscrew the four M4 x 12mm Ti thruster guard screws. Keep these screws in a safe place for reassembly.

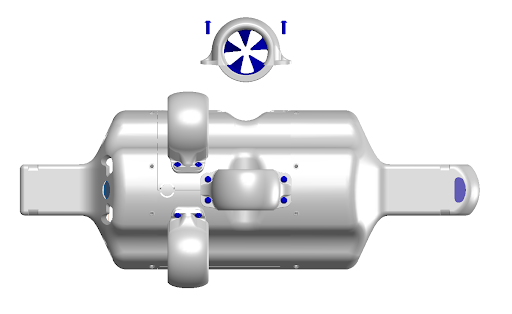

Hydrus Vertical Thruster Removal

Thruster Removal: Gently detach the thruster guard from the main body of the Hydrus. This should require minimal force. The impellor and the ceramic bearing are housed within the thruster guard.

Thruster removal

Component Separation: Separate the impellor and the ceramic bearing located inside the thruster guard. Further dismantle the two ceramic bearings from the impellor by gently pulling around the collar of the bearing

Impellor Assembly Separated

Note: Thoroughly inspect the thruster guard, the two ceramic bearings, thruster guard and the impellor for any signs of damage. Replace any components as necessary.

Note: It's crucial to handle ceramic bearings with care, as dropping them could result in damage, potentially rendering them unusable.

Note: Exercise caution to avoid applying any pressure on the impeller blades while extracting the bearings.

Impellor Identification (only applicable for legacy Hydrus hardware v1.0): Determine whether the impellor being replaced is a CW (Clockwise Impellor) or a CCW (Counter Clockwise Impellor).

Impellor Identification

Reassembly: Reattach the two ceramic bearings to the impellor and slide the assembly back into the thruster guard.

Thruster Re Assembly

Thruster Replacement: Carefully align and reattach the thruster guard to the main body of the Hydrus. Ensure that the thruster assembly is properly seated in the cassette. Insert and hand-tighten the thruster guard screws. By hand, test spin the newly mounted thruster assembly to ensure smooth and free rotation. If required, adjust tension on the mounting bolts to ensure on cross-torque is being applied to the guard that may prevent the Impeller from spinning.

Note: Adjust the torque on the mounting bolts as needed to prevent the force on the guard from obstructing the impeller's spin.

Thruster Replacement

Hydrus Complete

Note: Self-Test: After the thruster has been replaced and secured, conduct a Testing and Functional Checks to ensure the new thruster is functioning correctly.